Boss Air Suspension is the Boss

Boss are an Australian manufacturer and supplier of air suspension. There can be few environments quite as harsh as the Australian Outback, which is why many car manufacturers take their vehicles there to test them and try and break them to find the weaknesses. With over 15,000 kits supplied, using bags that are tested up to 750 or 1,000 PSI, there can be little doubt that these products are well up to the job. For such a tough environment you need a tough kit with equally tough bags – Boss is the Boss.

AirRide are able to offer the entire Boss Air Suspension range as UK distributor. Tough kits for vans or pick-ups (or as the Aussies call them, ‘Utes’!)

Load Support

The Boss Air Suspension range, supplied in the UK by AirRide, includes a selection of rear-end load-support kits for vans and pick-up trucks. These include very thick 6mm metal brackets and the Boss range of bags – some of the most rugged available.

These kits are added to leaf-spring (and some coil-spring) vehicles to add support for heavy weights, raise the rear and stabilise vehicles in all road and weather conditions. Air suspension offers a superior ride to up-rated metal springs, but also the ability to quickly adjust the support offered – either using a Schrader valve or a compressor-based system.

Bags

Boss is one of the few smaller companies to make its own bags. This has advantages for the after-market converter because much of the time, kit manufacturers are forced to source from what is available on the market. Boss are not limited in this way. These bags are made in Boss Air Suspension’s own facility, to their own specification. They are built for the rugged Australian Outback, which means they are tough and durable and up to the task of anything asked for them in the European market.

Single, double and triple-convoluted bags in 2400, 2500 and 2600 ranges.

Safety

The bags include nine high-tensile central wires around the waist, and a further four wires in each end at the bead. They are made from natural rubber, with woven inter-layer strengthening. End caps, like the brackets, are 6mm – thicker than the high-quality Dunlop products, which are 5mm.

Because of this spec, control and care, the bags are higher spec than most on the market – 160 PSI with burst pressures of between 600 PSI and 750 PSI (this basically means the bags won’t burst from normal use!) Since 2005, no bag has ever failed from bursting on a load-support application.

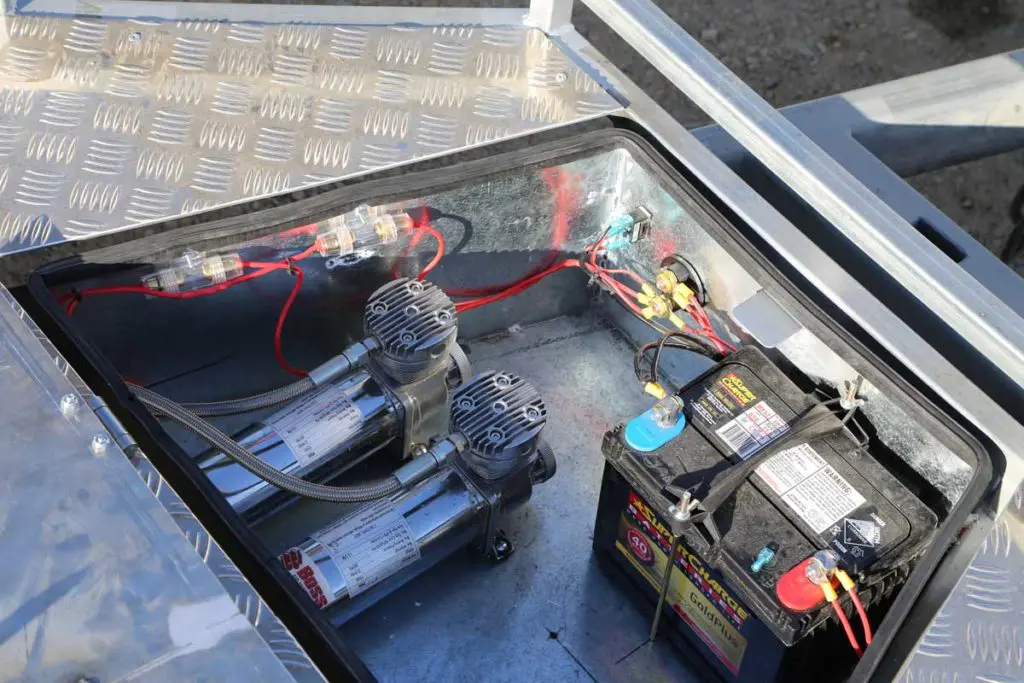

Aluminium Tanks

Aluminium tanks offer two main advantages over steel ones: Firstly, they do not rust in the same way or as severely, and secondly, they are lighter (and they look better!)

AirRide has used aluminium tanks for over ten years, from a time when the costs were prohibitive. As aluminium tanks have become more common place, costs have come down, and although they remain slightly more expensive than steel, they should still be the first choice for most.

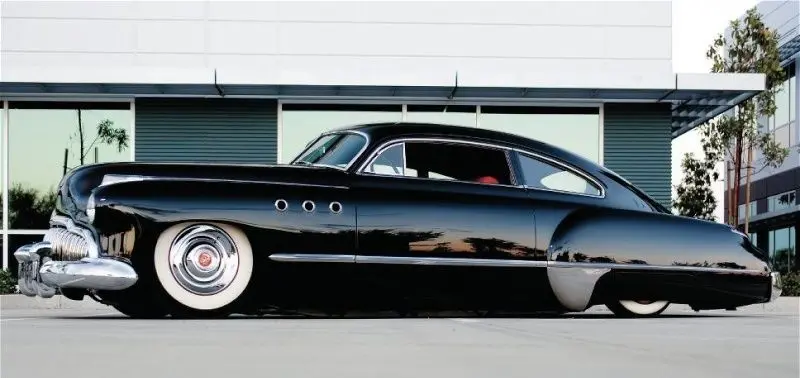

Trailer Suspension

Trailers towed behind cars, vans and pick-ups are ideal candidates for air suspension for all the same reasons air is used on vans and pick-ups. Air bag-equipped trailers handle better, ride better and are easier to load and hitch. They are also mercifully quieter to tow.

The range of trailer products is universal, so don’t expect a direct, bolt-on fit.

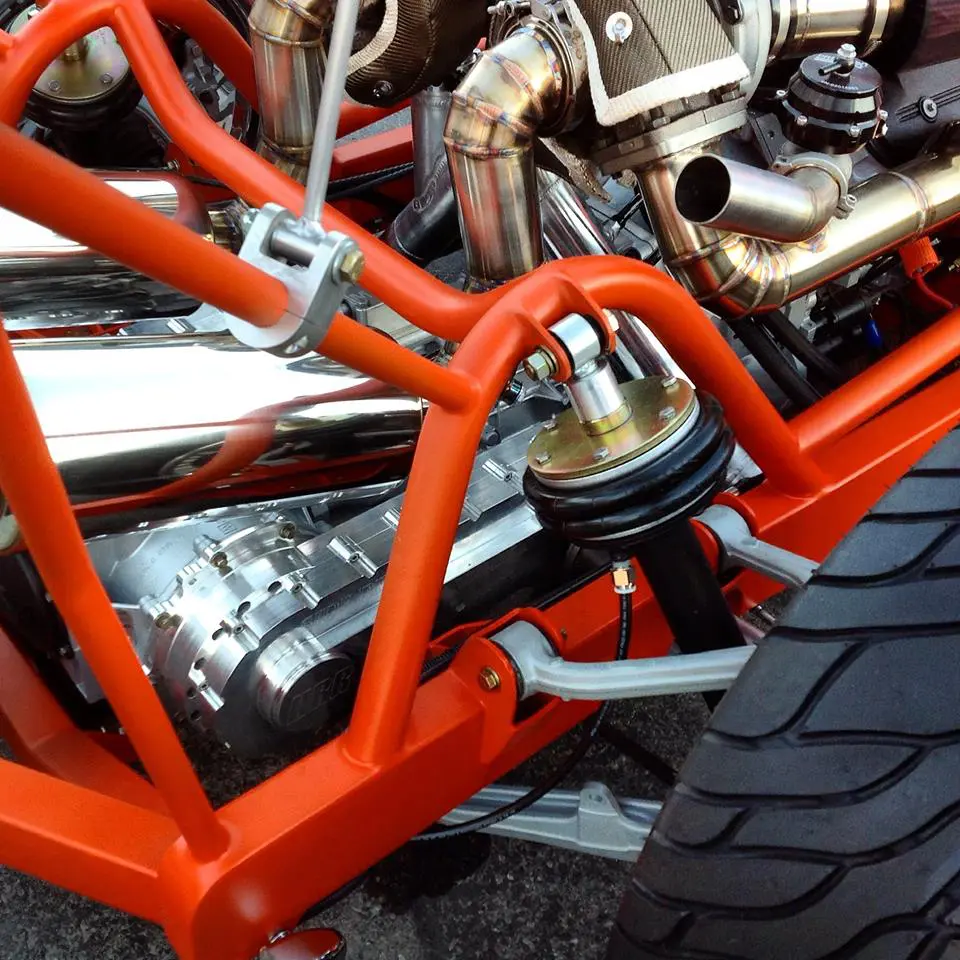

Universal Struts

For vehicles without a bolt-on kit, the alternative is usually a universal strut. These are struts without fittings which can easily be welded in place. This is ideal for highly-customised vehicles which will truly sit on the floor and for classic cars where kits are not available in the same range.

WHY BOSS PRODUCTS?

Quality Control

One in a hundred bags is tested to destruction in a controlled test chamber to pressures exceeding 750 PSI. This ensures the manufacturing and design of these bags is second to none.

Advanced Construction

Boss bags are made using advanced machinery, tested well beyond real world scenarios, and contain internal designs that ensure they are durable and reliable.

Made by Boss

Boss bags are made by Boss in their own dedicated facility. The bags have been evolving in terms of both durability and performance ever since they were first made, in 2005.

Leading Technology

Boss bags lead the way in bag-sealing technology, using forged rings.

Tough Brackets

6mm steel brackets on most kits mean they are tougher than most other kits on the market.

Easy to Install

Boss kits are easy to fit with most kits being a simple bolt-on installation.

Examples of Boss Air Suspension